18. 3. 2022

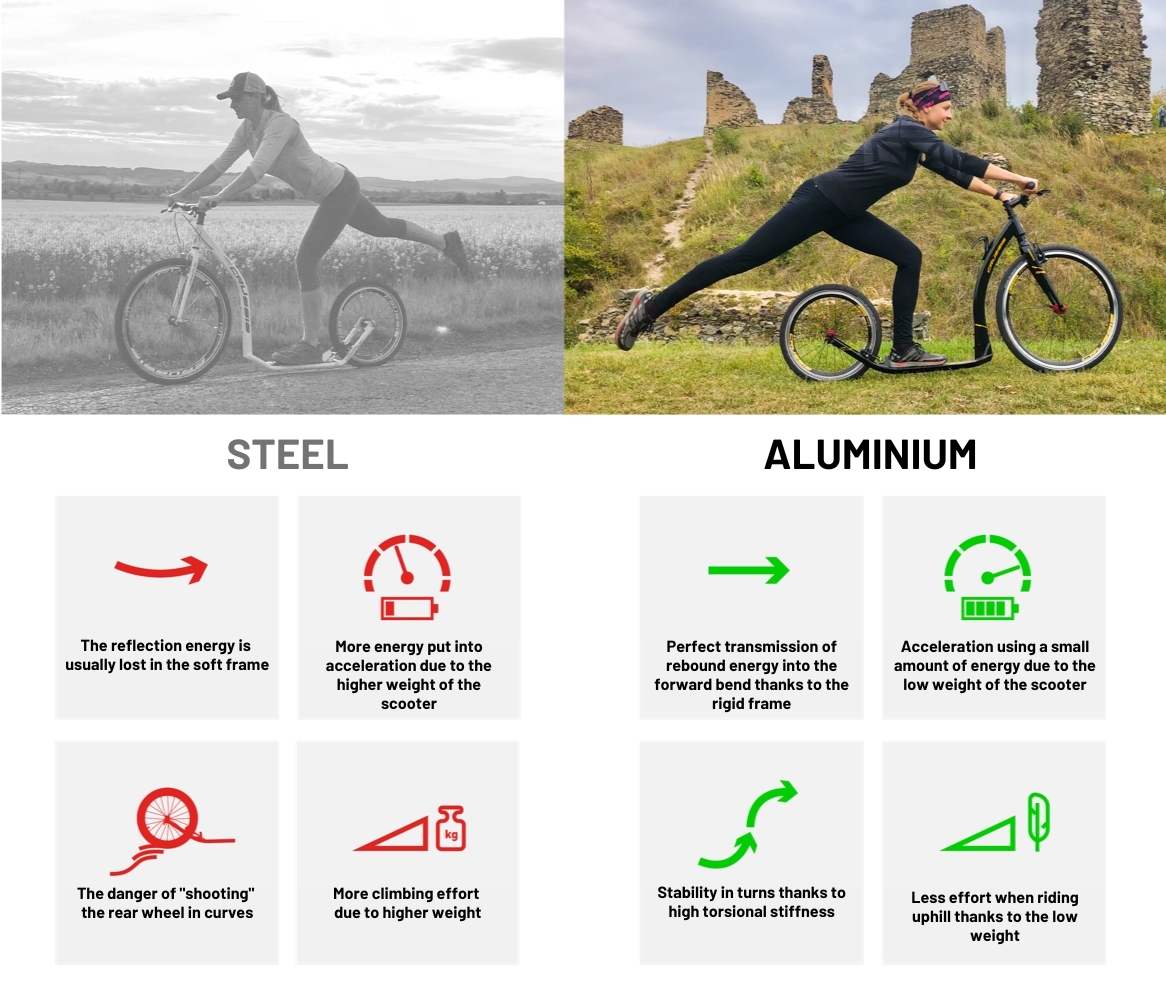

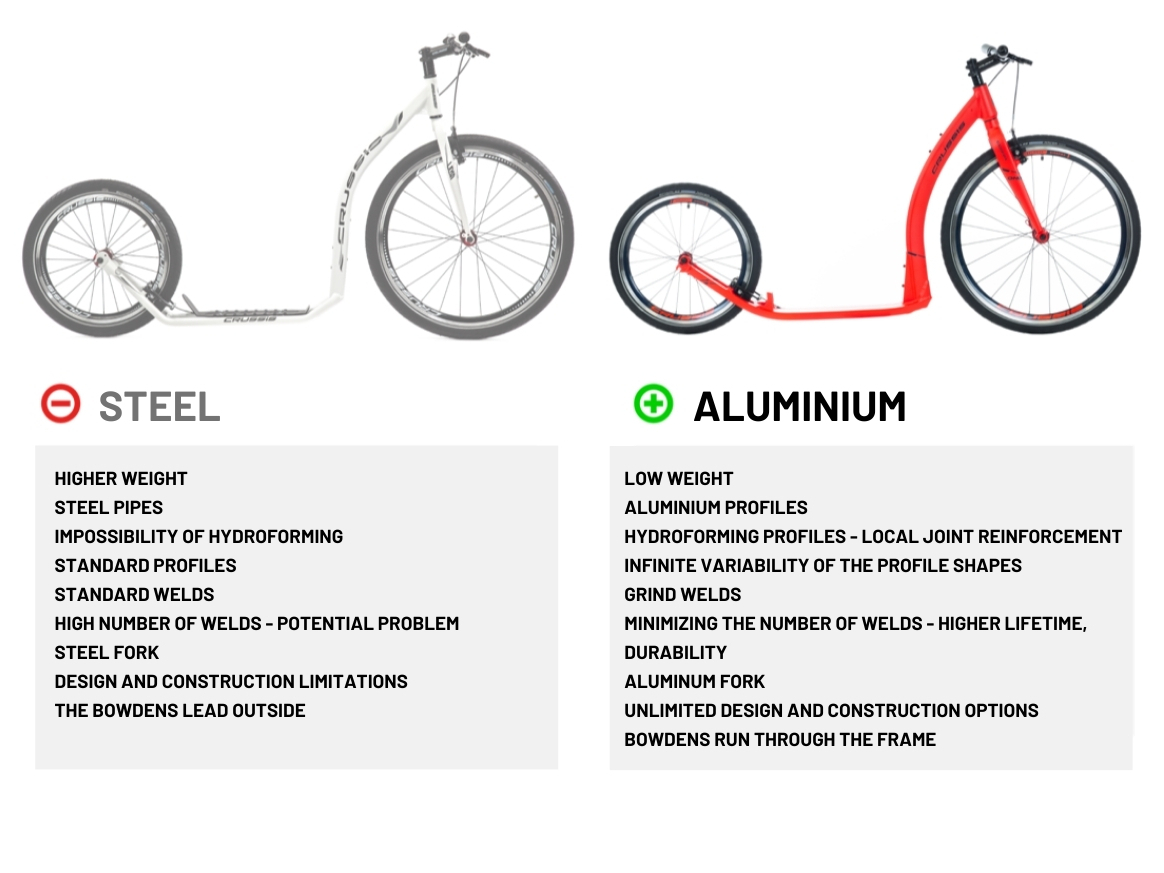

From the 2022 season, we are going full throttle to the production of aluminium scooters. We're out of steel. And not just here... Crussis scooter production has a history of more than six years. Our first machines rolled off the production line in 2015. And they were good scooters. At least for their time. But you can't stop time, so over the past few years we've kept a close eye on trends not only in the scooter industry, but especially in cycling. Technology, materials, components. That's why in 2022 we have definitively abandoned the production of scooters made of steel. In recent years, we have found that steel no longer has anything to offer us. Just like in the cycling industry, our industry has also hit its limits. Aluminum frames are now the dominant material in the bicycle industry. Of course, the best bikes are built on carbon frames, but for the average user, an aluminium frame is the number one choice because of the price/performance ratio. After all, the 2021 season, when we launched the first series of Crussis Cobra scooter models, proved us right. There is a huge demand for aluminium scooters and a shortage of them on the market. In fact, there are currently only three manufacturers that can build them, not counting the smaller garage brands. And we are one of them.

Because its properties surpass steel in almost every respect. Stiffness, light weight, ductility, corrosion resistance and thus a wide range of construction and design possibilities. Aluminum plays a major role in all of this.

We use 6061 T6 aluminium alloy for the frames. It is a structural alloy that is strong, easy to form, machine and weld.

The result is a frame that is strong, rigid and lightweight.

On such a frame we are then able to build a scooter that, thanks to the combination of all the advantages of aluminium, will ride better than scooters with a steel frame.

The use of aluminium in manufacturing is not enough in itself. Of course, the geometry and workmanship of the frame is important.

That is why the frame construction and the associated design was designed by an experienced Czech designer, consulted with a top aeronautical engineer and tested in the Czech Republic both in software and in real life. The development took two and a half years and thousands of kilometres were driven on test samples.

In the production of our aluminium frames we use a combination of drawn multi-chamber profiles (scooter footpeg) and hydroforming (scooter neck and fork). As a result, we were able to construct the scooter footpeg and rear fork from a single piece of profile, creating an uninterrupted, clean line of the footpeg portion of the frame. This is a unique technology that is unparalleled in the scooter world.

By eliminating welds at this node, we have achieved greater durability and production efficiency.

The frame design based on diagonal surfaces and sharp edges give the scooter a sporty character that follows its aggressive geometry.

The head tube in conjunction with the specifically designed fork then creates a unified whole, following the current trends in the cycling industry.

Scooter neck made of hydroforming tube

Double rear fork attachment for adjustable footrest height

With the advent of aluminium frames, we have abandoned the limiting powder coating and gone for wet painting. With a range of over a thousand shades, water-based paint technology has several advantages.

One of them is the possibility of using cut painting, a technique of painting multiple separate colours on one frame.

Although it is a laborious and therefore expensive technique, we used it on half of this year's collection.

In the development of our aluminium scooters, we have underlined and added up all of the above. The result was clear:

The lightest aluminium scooter on the market, with a weight of just 7.635 kg and a wheel d...

399 EUR

The lightest aluminium scooter on the market, with a weight of just 7.635 kg and a wheel d...

399 EUR

The lightest aluminium scooter on the market in simple design with a weight of just 7.635 ...

399 EUR

The lightest aluminium scooter on the market in simple design with a weight of just 7.635 ...

399 EUR

The new CRUSSIS aluminium road scooter ROAD with 28×20" wheels and a weight of just 7.40 k...

399 EUR

The new CRUSSIS aluminium road scooter ROAD with 28×20" wheels and a weight of just 7.40 k...

399 EUR

The new CRUSSIS aluminium road scooter ROAD in simple design with 28×20" wheels and a weig...

399 EUR

The new CRUSSIS aluminium road scooter ROAD in simple design with 28×20" wheels and a weig...

399 EUR

CROSS Hard 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with wheel d...

599 EUR

CROSS Hard 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with wheel d...

599 EUR

ONE CROSS 9.2 aluminum all-terrain scooter on top SRAM GUIDE T hydraulic disc brakes with ...

869 EUR

ONE CROSS 9.2 aluminum all-terrain scooter on top SRAM GUIDE T hydraulic disc brakes with ...

869 EUR

CROSS 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with a wheel diam...

649 EUR

CROSS 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with a wheel diam...

649 EUR

COBRA sport aluminum scooter in one-color design from CRUSSIS on top SRAM hydraulic disc ...

559 EUR

COBRA sport aluminum scooter in one-color design from CRUSSIS on top SRAM hydraulic disc ...

559 EUR

COBRA sport aluminum scooter in one-color design from CRUSSIS on top SRAM hydraulic disc ...

559 EUR

COBRA sport aluminum scooter in one-color design from CRUSSIS on top SRAM hydraulic disc ...

559 EUR

COBRA sport aluminum scooter in one-color design from CRUSSIS on top SRAM hydraulic disc ...

559 EUR

CROSS 9.2 aluminum all-terrain scooter on top SRAM GUIDE T hydraulic disc brakes with whee...

869 EUR

CROSS 9.2 aluminum all-terrain scooter on top SRAM GUIDE T hydraulic disc brakes with whee...

869 EUR

CROSS Hard 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with wheel d...

599 EUR

CROSS Hard 6.2 aluminum all-terrain scooter on top SRAM hydraulic disc brakes with wheel d...

599 EUR

COBRA Sport aluminum scooter from CRUSSIS on top SRAM hydraulic disc brakes with a wheel d...

559 EUR

COBRA Sport aluminum scooter from CRUSSIS on top SRAM hydraulic disc brakes with a wheel d...

559 EUR

COBRA Sport aluminum scooter from CRUSSIS on top SRAM hydraulic disc brakes with a wheel d...

559 EUR

COBRA Sport aluminum scooter from CRUSSIS on top SRAM hydraulic disc brakes with a wheel d...

559 EUR

COBRA Sport aluminum scooter from CRUSSIS on top SRAM hydraulic disc brakes with a wheel d...

559 EUR

The lightest aluminium scooter on the market, with a weight of just 7.635 kg and a wheel d...

399 EUR

The lightest aluminium scooter on the market, with a weight of just 7.635 kg and a wheel d...

399 EUR

The lightest aluminium scooter on the market, with a weight of just 7.635 kg and a wheel d...

399 EUR

The CRUSSIS COBRA is here! The lightest aluminium scooter on the market, with a weight of ...

399 EUR